As the market for electric vehicles and energy storage systems expands, lithium-ion batteries play a central role. This is because lithium-ion batteries have advantages such as high energy density and long life, making them a mainstream choice for electric vehicles and energy storage systems. This trend has promoted the rapid development of the lithium battery industry and also brought challenges at the production and management levels. Against this background, the widespread application of RFID technology has injected new vitality into lithium battery manufacturing.

RFID technology leads lithium battery innovation

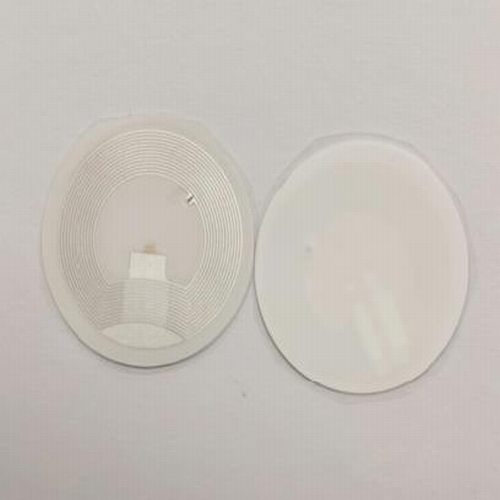

As a type of wireless automatic identification technology, RFID technology uses radio frequencies to identify items. Its application areas span many fields such as material tracking, inventory management, commodity tracing, and asset management. In lithium battery manufacturing, RFID gives full play to its advantages. By marking, identifying and tracking every link of the battery, it promotes the transparency, automation and controllability of the production and supply chain, providing higher intelligence for the entire production process. level.

The application of RFID technology in lithium battery manufacturing is obvious, especially in raw material management, and its contribution cannot be ignored. By installing RFID tags on raw materials, companies can record raw material information and inventory levels in real time. This comprehensive tracking method allows manufacturers to understand the unique identification, storage location, and warehousing information of battery raw materials, and then monitor inventory and consumption status in real time. This not only improves management accuracy, but also effectively addresses various challenges in raw material management.

1.Production line management

RFID technology plays a key role. In the production process of lithium batteries, RFID tags are applied to core components such as electrode sheets and separators in the form of unique identification codes and RFID chip data. This marking method records key information such as production status, production parameters and production quality, providing all-round tracking and monitoring of the production process. This not only helps optimize the production process and improve production efficiency, but also provides strong support for quality control.

2.Logistics management

RFID technology enables full-process monitoring and tracking of lithium batteries in logistics management. This includes the positioning of materials and products in production, emergency alarms, distribution route optimization, etc. Through the application of RFID, logistics costs can be reduced, the risk of resource waste and loss is also greatly reduced, and the efficiency and effectiveness of logistics operations have been significantly improved.

3.Traceability management

In terms of traceability management, RFID technology provides important data support for the entire lithium battery production process. From production date, production process parameters to quality inspection results, factory batches, etc., RFID technology records these important data and achieves comprehensive traceability and backtracking. This not only provides enterprises with the opportunity to correct potential quality problems, but also complies with regulatory and standard requirements, winning more trust for enterprises in the market.

The application of RFID technology in the lithium battery industry is leading a new trend in smart manufacturing. It provides complete RFID solutions and technical support for lithium battery manufacturers, realizing an intelligent and paperless manufacturing management process. The application of this technology is not only to improve production efficiency, but also to promote the intelligent and scientific development of the entire industry. The widespread application of RFID technology has brought strong technical support to the lithium battery industry and will inject more impetus into the future development of the industry.

Conclusion

As the market for electric vehicles and energy storage expands, lithium-ion batteries become a mainstream choice, creating production management challenges. RFID technology is widely used in lithium battery manufacturing to achieve transparency, automation and controllability of production and supply chains through marking, identification and tracking. In terms of raw materials, production lines, logistics and traceability management, RFID technology plays a key role in improving management accuracy and production efficiency, reducing logistics costs, and enhancing market trust.